What’s up with Passive and Active shipping systems?

According to TPL Insight Magazine, reducing or preventing product deviations or excursions is the top priority for 69% of cold chain clients.

*TPL Insight Magazine

Issue 6, 2014

Choosing the right system, Passive or Active, brings you a long way towards obtaining stable temperatures and safe deliveries of your precious substances.

So, which cold chain solution is best for me and my company?

.

The Passive Shipping Configuration.

Passive shipping configurations are manufactured systems. In other words, they englobe an insulated design, using polystyrene, polyurethane or vacuum insulated panels.

Many such designs are pre-qualified to conserve materials at a particular temperature, for a certain amount of payload capacity, over a specified period of time: 24, 72 or 96 hours, and more.

A shipper will choose the optimal pre-qualified design, based on the client’s exact specifications.

To maintain the desired temperature, he may use gel packs or other types of Phase Change Materials (PCM).

If an off-the-shelf pre-qualified design doesn’t do the trick, transporters can customize a solution for a company’s specific needs.

As far as cost, passive systems are more or less expensive. Starting with very basic, inexpensive polystyrene collers, more complex configurations – using phase change materials and vaccuum insulated panels – may cost several hundred Euros.

.

The Active Shipping Configuration.

Active shipping configurations tend to be leased containers with advanced temperature controls. Attached to the containers are electricity or battery driven control elements which cut in to stabilise temperatures.

Some container units may have a heating and/or cooling system built in, and others use dry ice as a coolant.

Active shipping systems are usually designed to hold one or more pallets and, as such, are ideal for larger shipments.

It is fair to say that active shipping configurations are considered to be more secure than passive systems.

..

![]()

The Tutorial – Passive and Active shipping solutions.

.

Lesson 2 – Discover your passive versus active Needs Profile.

.

Some privileged clients have in-house experts whom they call in to evaluate each shipment’s specific needs. Such experts have experience and in-depth professional knowledge to propose and implement an optimised packaging solution.

But many organisations do not have in-house resources who have the time and breadth of knowledge to make informed decisions.

Working hand in hand with an external cold chain transportation specialist makes it possible for all clients to benefit from experts and tap into their “real life” experiences, applying both passive and active solutions.

Independent of whether you partner with internal or external logistics professionals, your exchange will be all the more efficient (and pleasant) if you’re able to communicate your needs clearly.

To help you with your communication, we provide 3 Needs Profile Checklists.

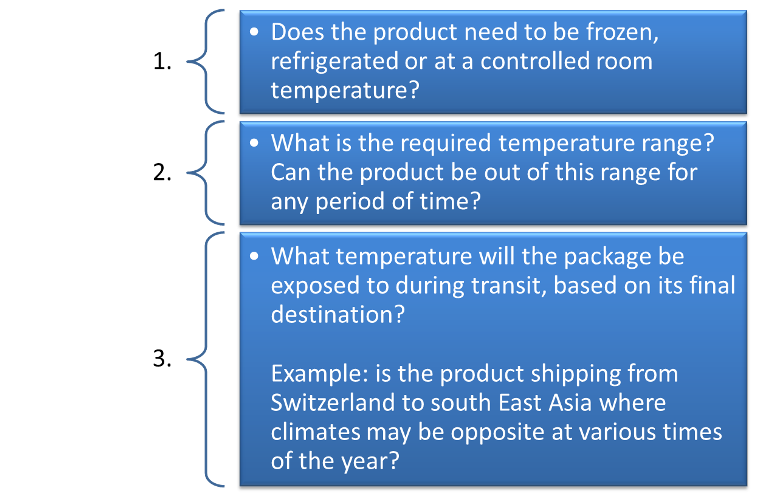

1. The Temperature Checklist

Please click on the image to download and print an easy-to-read PDF template.

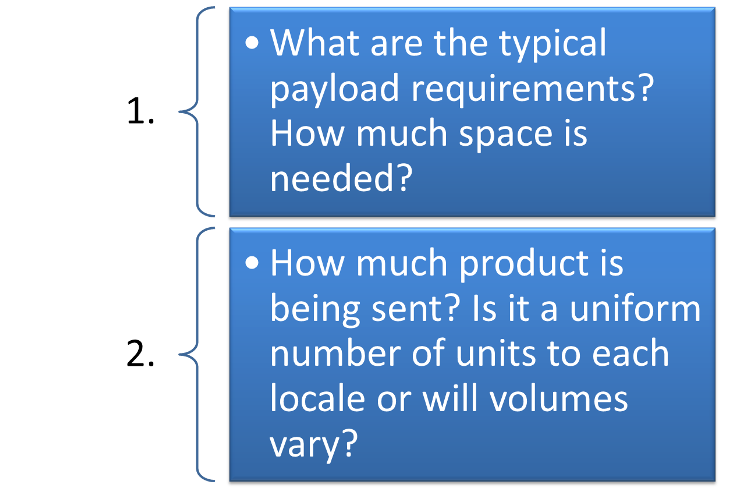

2. The Product Volume Checklist.

Please click on the image to download and print an easy-to-read PDF template.

3. The Transit Times Checklist

Please click on the image to download and print an easy-to-read PDF template.

Conclusion

Your active or passive shipment decision will need to take into account a myriad of different elements.

This is why we designed the above 3 Needs Profile Checklists, ready for you to download and use each time you initiate a shipment. They will enhance the communication flow between yourself and your cold chain shipping expert.

Our motto: whatever we can do to enhance your knowledge will help us serve you better!

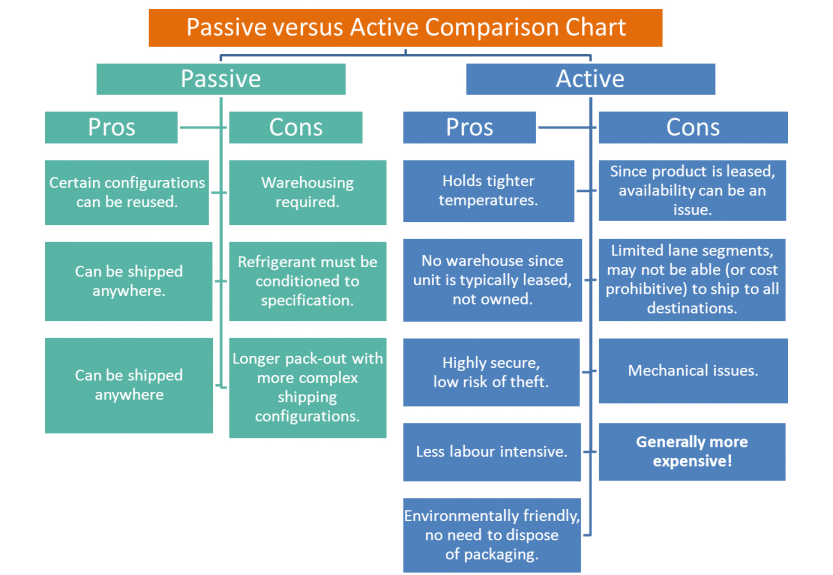

We conclude this Lesson with the Passive versus Active Comparison Chart and hope you’ll find it useful.

Passive versus Active Comparison Chart.

Once again, click on the image to download and print our easy-to-read PDF infographic.

About the “How to get cold chain shipping right” tutorials.

We give you 3 Lessons, spanning over 3 separate articles.

In Lesson 1 – Setting the scene for best value (1/3) – we talk about actionable guidelines for lean cold chain shipping.

In this Lesson 2 – Active and Passive shipping solutions (2/3) – you discover the intricacies about passive versus active cold chain configurations.

Lesson 3 – Smart Cold Chain Shipping. A case study (3/3) – presents a concrete example which unveils the process we use at N/V Logistics to achieve optimal cold chain configurations.

Disclaimer:

Whilst we strive to make our articles and tutorials as accurate as possible, NV Logistics SA cannot be held responsible for any changes in rules & regulations initiated by various worldwide organisations, including governments and others.